- TOP

- FEATURES

Five new

strengths and features

No filter cleaning required

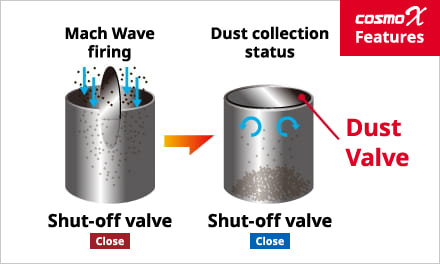

Cosmo's unique cleaning system, MachWaveMV3, is the latest and most effective cleaning technology that generates supersonic shock waves. Even when using fiber laser cutting machines, there is absolutely no need to clean the filters manually!

The powerful cleaning performance and uniqueness of our machine are recognized not only in Japan but worldwide, and we hold numerous international patents.

During the dust collection operation, Cosmo Clean ensures that the filters are properly cleaned and function efficiently. Equipped with a 'pressure regulating valve' that equalizes the internal pressure inside the filter with the external pressure during dust collection. This valve instantly reduces the pressure difference between the inside and outside to below 0.1 kPa, allowing the cleaning process to be completed within just a few seconds. Once cleaning is finished, Cosmo resumes maximum airflow and continues dust collection.

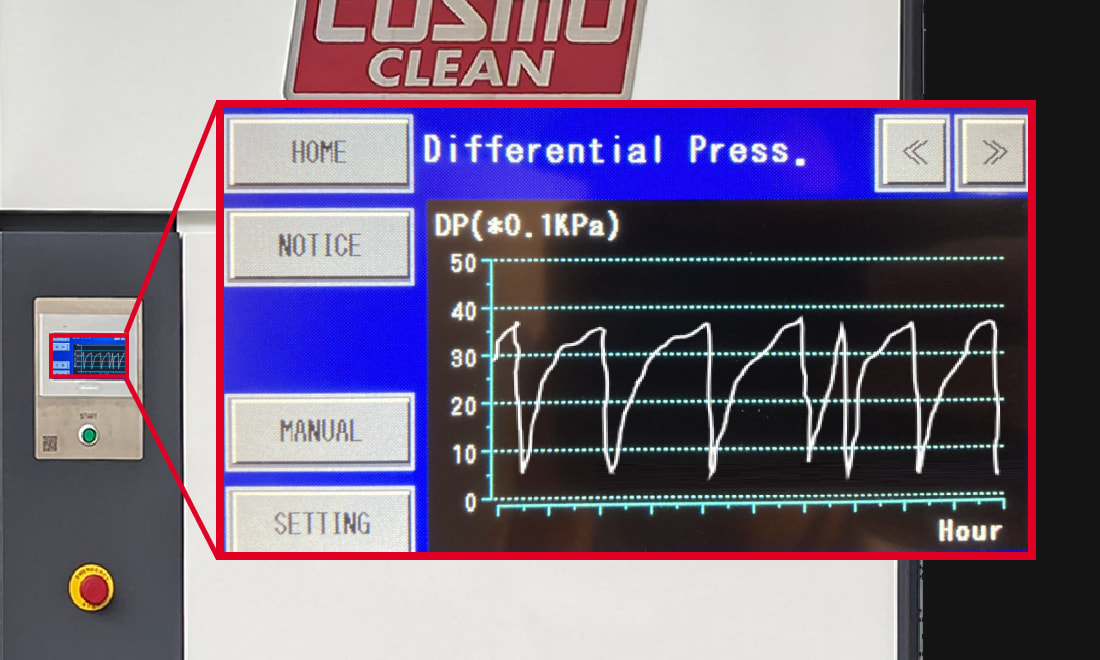

Equipped with a "smart control function" that determines the timing for filter cleaning.

Automatically maintains

consistent high dust collection efficiency

consistent high dust collection efficiency

"Smart Control" function equipped in Cosmo minimizes the reduction in airflow volume and power caused by filter clogging. The entire system is automatically adjusted to ensure that MachWaveMV3 operates more effectively. As a result, it maintains high airflow for a longer period and continues to perform effectively even in more challenging environments, such as during high-speed cutting with high-power fiber lasers.

Our goal is to contribute to the world by protecting people's health and keeping the environment clean.

During the disposal of the fumes, doesn't scatter around.

The dust collected by the Cosmo Clean machine forms into small flakes, preventing scattering or spreading during disposal. Cosmo simplifies exhausting and unpleasant dust-disposal processes. It also helps protect health by capturing harmful particles, keeps the environment and workwear clean, and significantly improves work efficiency.

Fumes generated during the cutting or welding of stainless steel may not form small flaky particles. For more information, please contact us.

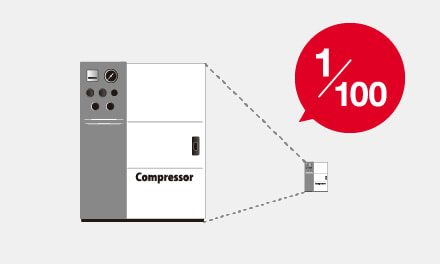

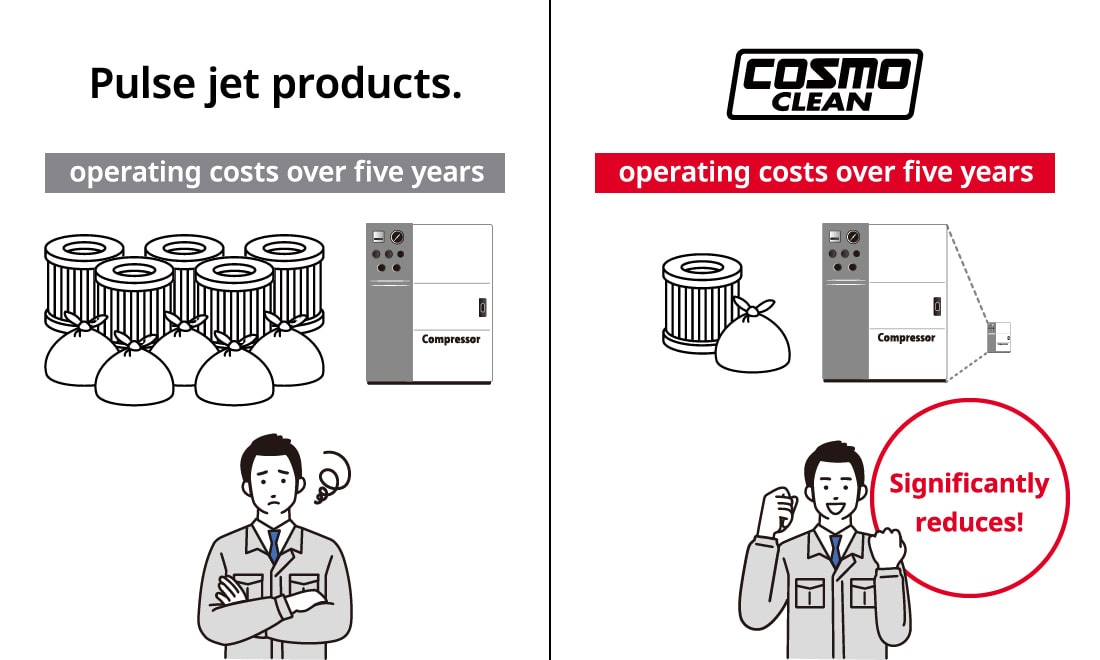

Number of parts that wear out over time is low, operating costs are also reduced.

Cost-effective product

The high operating costs of standard pulse-jet systems can be reduced with Cosmo Clean, which requires fewer consumables and is easier to maintain!

Previously, filters needed to be replaced annually, but now they only need to be replaced every five years. As a result, the costs for purchasing new filters and disposing of old ones are reduced. Additionally, since there is no need to clean the filters, labor costs for workers and electricity costs for the company are significantly saved.

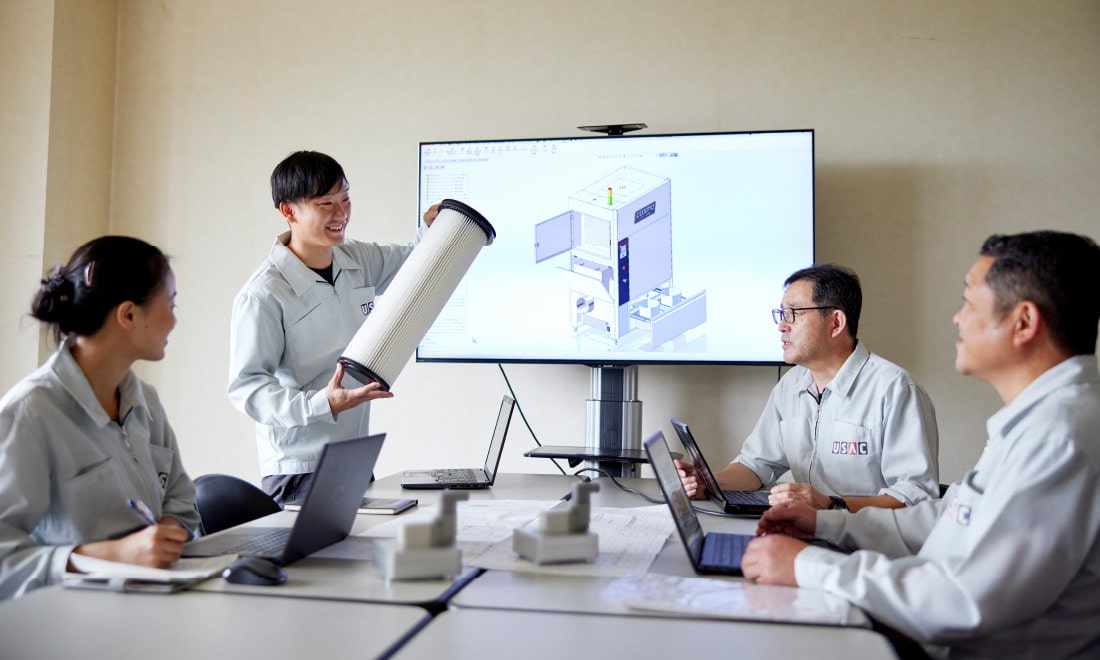

COSMO has been designed and manufactured by a company that is familiar with your needs and considers your requirements.

High-performance, high-quality dust collector

The development and production of Cosmo Clean is carried out by USAC, a company that deeply understands the needs and problems of the metal processing industry. Our unique and unprecedented technology has enabled us to achieve effective performance in improving production efficiency and the working environment. Through integrated "quality control" at our own factory, this led to the creation of Cosmo Clean, which ensures high-level performance.